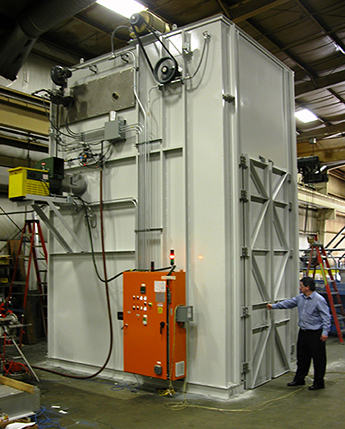

Oven for Curing Electrical Power

Distribution Equipment Components

Infratrol Ships Ovens for Electrical Power Distribution Equipment

May 15, 2014

- For curing epoxy high voltage power transmission components

- 160º C temperature, +/- 3 º C Uniformity

- 4 heated shelves, 39” wide by 44” deep inside dimension

- Product load: 2965 lbs.

Special Features

- Carbon Dioxide Sensor – CO2 gas detector with flow cap assembly.

- Aluminized Steel and Mild Steel Plate Can Construction – Mild steel welded airtight limits fume emissions. Mineral wool insulation keeps heat transfer to outer shell at a minimum.

- Exhaust Fan – Belt driven, centrifugal fan and motor exhaust all combustion products. VFD reduces exhaust air flow to NFPA safety standards.

- Gas Convection Equipment – Stainless steel tube high efficiency heat exchanger provides indirect firing heat. Integral blower supplies air and burner is equipped a prefabricated valve train.

- Electrical Control – Provides rapid oven heat-up and precise temperature control. Magnetic motor starters and complete safety system to meet NFPA standards.

Oven for Curing Epoxy High Voltage

Power Transmission Components

Ref. # 7630